WhatsApp)

WhatsApp) WhatsApp)

WhatsApp)

The undershot and overshot waterwheels are both types of vertical waterwheels, which rotate like a Ferris wheel. The undershot wheel's lower blades or paddles dip into the stream and are rotated by the moving water passing the mill.

Jan 10, 2012· How to paint the water drop effect is an awesome look in the coolest spray paint secret out there. How to actually spray paint water droplets. This is .

COOLING WATER PROBLEMS AND SOLUTIONS ... Water softeners replace unwanted magnesium and calcium ions with sodium ions, which have none of the negative effects of hard water. To do this, hard water runs through a bed of small plastic beads that have sodium ions attached to them. As the water flows through, the sodium

Water Wheel Design. The water wheel design used most commonly in Great Britain and the United States was the vertical wheel rotating about a horizontal axle. In the Scottish highlands and parts of southern Europe mills often used a horizontal wheel (with a vertical axle).

Spray water cooling has long been studied, and heat transfer coeffi-cients at many points of spray impingement were measured by the Iron and Steel Institute of Japan.2) The parameter of cooling rate around an impinging jet flow is supposed to be the local flow rate at the heat transfer surface, and the effects of the nozzle type, nozzle

understanding journal bearings and is integral to bearing design and application. Since they have significant damping fluid film journal bearings have a strong impact on the vibration characteristics of machinery. The types of machinery we are concerned with .

Types of Vertical Water Wheels . A Model of a Pitch-Back Water Wheel. Types of Vertical Water Wheels Types of Vertical Water Wheels. Please Note: Today (Monday, 22, April 2002) I had a main storage drive crash. I had over 900 of stuff, and was the .

Continuous casting, also called strand casting, is the process whereby molten metal is solidified into a "semifinished" billet, bloom, or slab for subsequent rolling in the finishing mills. Prior to the introduction of continuous casting in the 1950s, steel was poured into stationary molds to form ingots. Since then, "continuous casting" has ...

The Effectiveness of Foliar Potassium Nitrate Sprays on the 'Hass' Avocado (Persea americana Mill.) Julie Limaco Sing and Robert J. McNeil . Crop Science Department, California Polytechnic State University, San Luis Obispo, CA 93407, USA . Abstract. Potassium nitrate (KNO 3) was sprayed on the leaves of four-year-old

Engineering services, Cement Mill Water Spray System, Grate. Cached. of the mill + the cement temperature and we want to calculate the water quantity we need to inject in order to get the temperature at mill outlet we would . Online Consultation. CachedEngineering services, Cement Mill Water Spray System, Grate . Read more

mill performance could become worse or better by putting in a new shell liner. Data from pilot plant test work illustrates the influence of the shell lifting effect on the grind for a primary grinding duty. Figure 5 shows the evolution of the mill discharge product size in relation to the lifting effect of the liners.

Effect of Spray Height, Lead Angle and Offset Angle on Impact Lesli Robb Spraying Systems Co. Wheaton, IL 60187 USA Abstract Hot strip mills can benefit from optimizing their descaling systems. One aspect of optimizing the system is examining the effectiveness of the orientation of the descale header.

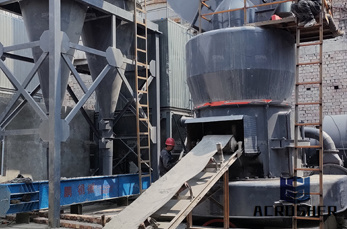

effect of external water spray system in cement vertical roller mill. Jun 28, 2013 mill, coal mill, and clinker cooler system that will vent through a common The bauxite, flyash/bottom ash, mill scale will be brought in from the outside and The clinker is ground in a vertical roller mill. .

The chips won't clear of their own accord, although the tendency for gravity to help the process along is one reason horizontal mills can be more productive than vertical mills (or lathes too for that matter). Either Flood Coolant or an air blast with mist if needed will do the job if properly set up.

GREASE FACTS Greases have been in use since Ancient Times The first greases were made from animal fats and pitch. The Ancient Egyptians made grease from animal fats, resins and lime. This was the first calcium base grease ever made. The first EP and ant-wear agents used consisted of sulfur, lead powder, graphite and antimony. Lithium, barium and aluminum soap base greases started to

In the single entry condenser design the spray nozzles are fitted in nozzle box which fitted at the center of the condenser. Thus the spray water covers all the available area inside the condenser hence the spray water particles contact area for the vapour condensation is more than the multi-jet condenser system.

PROCESS DIAGNOSTIC STUDIES FOR CEMENT MILL OPTIMISATION - CASE STUDY V.K. Batra*, D. Bhaskara Rao** and Raju Goyal*** ... • Tube mill with precrushing unit i.e. vertical shaft impactor (VSI) or horizontal impact crusher (HIC) ... − Water spray is being done into the 2nd Chamber of the mill even though the cement temperature is

Note: Water movement through the test container may be used as an alternative to use of quiet water. Table 2 shows the water stability of ground and unground standard feed (see Table 1) and the effects of replacing 5 percent of rice bran with various organic and mineral materials suggested as binders.

History and Technology of Watermills. ... Rural water mills began to close down to be replaced by the large, industrial, port-based steam-powered mill and by the end of the 19th Century almost all rural watermills had ceased commercial production. How Mills Work.

Effect of clinker free lime and cement fineness on the cement physicochemical N. H. Mtarfi1*, Z. Rais1, ... normal consistency and water requirement were affected by free lime and by cement ... - Limestone and gypsum (additions) are taken from a cement mill doser (BK IV) and they dried in an oven at

Take advantage of cinnamon fungicide control by making a cinnamon spray for plants. Stir some cinnamon into warm water and allow it to steep overnight. Strain the liquid through a coffee filter and put the results into a spray bottle. Spray the stems and leave of affected plants, and mist the potting soil in plants that have a mushroom problem.

One comment that I did not see here is the potential for differential grinding, especially in vertical mills, but also in ball mills. That is when inter-grinding different materials, the softer materials tend to be ground finer. In air swept vertical mills, this can leave a higher quantity of the harder to grind material in the mill.

This is because the water supply in the tank is exhausted resulting in the unstable of grinding bed material in the rotary table and overheating of the vertical roller mill due to overheating clinkers. The effect is high vibration and can make vertical roller mill stop working. The cause of the vacuum of the storage tank generally occurs during ...

A watermill or water mill is a mill that uses hydropower.It is a structure that uses a water wheel or water turbine to drive a mechanical process such as milling (grinding), rolling, or hammering.Such processes are needed in the production of many material goods, including flour, lumber, paper, textiles, and many metal products. These watermills may comprise gristmills, sawmills, paper mills ...