WhatsApp)

WhatsApp) WhatsApp)

WhatsApp)

Jul 01, 2003· Home » Choosing the Best Media Mill For Your Wet Grinding Application. Choosing the Best Media Mill For Your Wet Grinding Application ... the more energy you can input into a batch, the more grinding action is achieved. ... Dr. Stehr, Norbert (1984), Residence Time Distribution in a Stirred Ball Mill and Their Effect on Comminution", DRAIS ...

Mar 08, 2013· calculation of ball mill grinding efficiency. dear experts . please tell me how to calculate the grinding efficiency of a closed ckt & open ckt ball mill. in literatures it is written that the grinding efficiency of ball mill is very less [less than 10%]. please expalin in a n excel sheet to calcualte the same. thanks. sidhant. reply

Ball mill is a key equipment to re-crush primary crushed materials. Ball mills are widely used in cement, silicate products, 52555 new building materials, refractory materials, fertilizer, ferrous and non-ferrous metals and glass ceramics and other production industries.

Hi all, I am wondering about the time of grinding in ball mills. How can I calculate the retention time? Which parameters should be considered? Thanks in advance..

Since the inception of our company, we manufacture and supply the best quality of Batch Ball Mill. Available with us in various specifications, the rendered batch type ball mills are used to grind coarse materials into fine powder. By using advanced machinery, we manufacture the batch type ball mills as per the industry laid

In the batch mode, material is charged into the mill at the top, ground for a predetermined time, then discharged through grids at the bottom. The system can easily be sealed for grinding under inert gases such as nitrogen or argon. The SD Attritor is also used to make dispersion-strengthened metal (DSM).

D = Internal Dia of the Mill in cms. after lining L = Internal length of the mill in cms. after lining. To calculate grinding media charge for continuous type ball mill, M = 0.000676 x D2 x L Example - To calculate grinding media charge for a 180 cm dia x 180 cm long batch type ball mill with Duralox 50 mm thick bricks. Formula to be used is

To calculate grinding media charge for continuous type ball mill, M = 0.000676 x D2 x L Example . how to calculate cement grinding mill balls charge – Mining FLshanghai ball mill for cement grinding. cement mill is a corrugated lining designed to obtain maximum power .

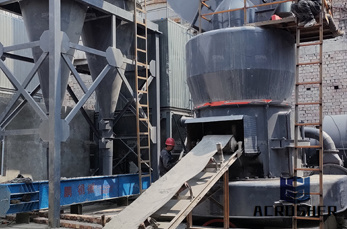

Batch Ball Mill Introduction: Batch ball mill, sometime we call it ceramic ball mill, also called one time feeding materials grinding mill,can adopt the intermittent work,widely used for the ceramic materials,K-feldspar,quartz sand fine grinding,and coating materials mixed grinding,this ball mill can adopt different liner type according production and design,to satisfy different requirements ...

involve grinding). With Lloyd's ball milling book having sold over 2000 copies, there are probably over 1000 home built ball mills operating in just America alone. This article borrows from Lloyd's research, which was obtained from the commercial ball milling industry, and explains some of the key design criteria for making your own ball mill.

ball mill charge calculation per size rainbowridersin Calculate and Select Ball Mill Ball Size for Optimum In Grinding selecting calculate the correct or optimum ball size that allows for the best and optimumideal or target grind size to be achieved by your ball mill is an important thing for a Mineral Processing Engineer AKA . Live Chat

grinding mill calculation in ime Grinding Time Calculation – Grinding Mill China. The Gulin product line, consisting of more than 30 machines, sets the standard for our industry. We plan to help you meet your needs with our equipment, with our distribution and product support system, and the continual introduction and updating of products.

Jun 23, 2016· calculate grinding time batch ball mill. How To Calculate Grinding Rate Of. grinding mill calculation in ime. Download this PDF file Redfame Publishing. The energy required to grind one tonne of an ore from a given feed size to a specified product size is a material.

May 22, 2019· The ball mill consists of a metal cylinder and a ball. The working principle is that when the cylinder is rotated, the grinding body (ball) and the object to be polished (material) installed in the cylinder are rotated by the cylinder under the action of friction and centrifugal force.

Batch ball mill is also called ceramic ball mill, with drying work and weting working by batch. It is used for fine grinding of feldspar, quartz, clay, ore, etc. Batch ball mill (ceramic ball mill) is mainly used for mixing, milling of the materials. It works with less energy but produces high fineness product.

The ball mill can grind various ores and other materials either wet or dry. There are two kinds of ball mill, grate type and overfall type due to different ways of discharging material. Many types of grinding media are suitable for use in a ball mill, each material having its own specific properties and advantages.

2 MODELLING THE SPECIFIC GRINDING ENERGY AND BALL-MILL SCALEUP Ball-mill scale up (Bond's Law)Data: zBond work index w i zFeed D f and product d size (both 80% cumulative passing) Result: The specific grinding energy w Mill power draw P = wT, where T the mill capacity Mill dimensions (from Tables or charts)

Ball mills work well on hard, brittle materials. They are not as suitable for grinding elastic, ductile or fibrous materials, or for fine grinding in general. Ball mills can blend and grind at the same time, yielding a fine, intimate mixture. Conventional ball mills are usually limited to a particle size of 1µ after one hour of grinding

Ball mill operation is often regarded as something of a mystery for several reasons. Ball milling is not an art - it's just physics. The first problem will ball mills is that we cannot see what is occurring in the mill. The other problem is that many of the independent variables .

Grinding Abstract In ball milling the rates of breakage vary primarily with the size distribution of powder in the mill. Using an approximate solution to the batch-grinding equation, the acceleration and deceleration of breakage rates of all individual size classes are determined when the grinding environment is varied. Experimental results with

Dry grinding experiments on cement clinker were carried out using a laboratory batch ball mill equipped with a torque measurement. The influence of the ball size distribution on the specific selection function can be approached by laboratory runs using mono-size balls. The

It is assumed that the ore is continuously discharged from the feeding port to the discharge port. The ball milling time calculated under this ideal state is the minimum grinding time. The filling rate of the ball mill is 40%. If the slurry level reaches 50% filling rate, the slurry will flow out automatically.

breakage parameters can be determined from mono-size, short grinding time batch tests. The determined ... for wet grinding in overflow ball mills to scale-up results from laboratory tests to larger mills S JDi (1 0.937 ), 2.4 m (4) Beeck R. (1970) proposed that for dry grinding of

calculate grinding time batch ball mill. Posted at:January 4, 2013[ 4.7 - 3955 Ratings] ... As wet ball mill grinding is a . Calculate ball charges and. About Price. Grinding | Quaker Chemical Corporation. CALCULATIONS There are many different types of calculations ... Parts are placed in the process one at a time and the grinding wheel moves ...