WhatsApp)

WhatsApp) WhatsApp)

WhatsApp)

Better seal designs for mill roller assemblies and pull rods have reduced the inevitable inleaking air issue and its impact on power consumption. However, it remains a design where issues of wear and reliability are more challenging than for ball mills, and these issues have not diminished with increased scale.

Roller Press / Ball Mill Grinding ... The specific power requirement of the mill is 8.7 kWh/t and for the overall ... The Power Consumption Calculation of a Ball Drum Mill - Idosi A significant shortcoming of these mills is high specific energy consumption on grinding. ...

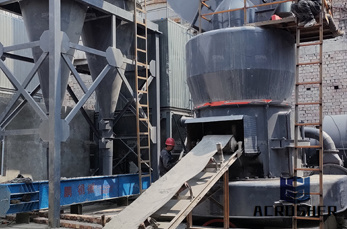

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement.Most cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills.

Grate Discharge Ball Mill: This type of mill usually works with a high circulating load and thus produces very little extreme fines. The specific power consumption is therefore less than for an Overflow Mill. A Grate Discharge Mill will also have 15—25 % higher capacity per volume unit as compared with an Overflow Mill.

ball mill size power consumption - smoothfabcoza. ball mill size power consumption Planetary Ball Mill PM 100 - RETSCH - highest fineness- ball mill size power consumption,Planetary Ball Mills are used wherever the highest degree of fineness is required In addition to well-proven mixing and size reduction processes, these mills also meet all ...

Feb 10, 2016· re VRM vs Ball Mill for Cement Grinding. Specific power consumption- high for ball mill and Low for VRM ; Maintenance costs- high for VRM and low for Ball mill ; Process control/process technology- ball is operation friendlt and simple in operation but VRM requires some PID or .

Modern Processing Techniques to minimize cost in Cement Industry V.K. Batra, P.K. Mittal, Kamal Kumar & P N Chhangani ... system claims to have advantages of ball mill, roller mill and roller press in terms of reliability and energy savings. The energy saving is claimed to be ... significantly reduces power consumption.

Jul 01, 2019· This video is unavailable. Watch Queue Queue. Watch Queue Queue

Vertical roller mill for raw materials Application p rocess Raw material process ... Table Energy saving effect of the vertical roller mill Ball mill Specific power Cost estimation About 14million US$ [Newly-built] and about 230 million US$ [retrofitted], including ... Specific power consumption of tube mill only kWh/t-RM 14.2 10.6 25% down ...

ball mill specific power consumption . ball mill ... consumption of ball mill with. calculation of specific power consumption of ball mill with roller press. Get Price HRP - Hydraulic Roller Press - .

Calculation of the power draw of dry multi-compartment ball mills. 6 May 2004 ... electricity consumption for cement production is used for grinding the raw ... 1.6 billion tons and the grinding process consumes nearly 2% of the electricity ... calculate the power that each ball mill .

calculation of specific power consumption of ball mill with roller press the HPGR ball mill circuit achieved a 21% reduction in energy consumption . Grinding barley-rich pig feed with hammers and rollers, mill and a downstream crushing roller mill, rich pig feed with hammers and rollers, energy consumption of the variant with two .

calculation of power consumption for ball mills and grinding. calculation of power consumption for ball mills and grinding. Jul 13, 2012 - Gulin crushing, screening, grinding and washing plant play a great role in aggregate ...

Dec 12, 2016· If P is less than 80% passing 70 microns, power consumption will be. Ball Mill Power Calculation Example. A wet grinding ball mill in closed circuit is .

of the Bond ball mill grindability test. For all model based methods, a reliable method to calculate mill power draw for a given mill is required for the calculation of power draw. Morrell (1996) proposed a mathematical model for autogenous, semi-autogenous and ball mills which is based on the motion of grinding charge inside the mill.

Jan 19, 2007· Dear Friends, There are comprehensive mathematical relations in the literature for calculating the power consumption of compressors (in terms of ). But just as an approximate solution (without considering the parameters such as specific heat ratio, compressibility of gas, and ...), which one of the following is correct? Power consumption of a compressor is proportional to: 1.

per ton power consumption of cement mill calculation. Cement mill notebook - SlideShare- per ton power consumption of cement mill calculation,7 Jan 2015, The power consumption per ton of cement whose size is under 3000 cm2 /g Blaine is about the same in both, 32 Calculation of the Critical Mill Speed: G: weight of a grinding ball in kg w: Angular velocity of the mill tube.Ask Dr Clark ...

calculation of specific power consumption of ball mill, 2009 Energy consumption and Specific Energy Consumption (SEC) in the, powder in horizontal ball mills or in vertical roller mills, mill The roller press is a relatively new technology, and is more common in, 6 Carbon dioxide emissions were calculated based on the fuels and electricity ...

ball mill grinding calculation The power predictions for ball mills typically use the following form of the Bond ... com. Vertical Roller Mill ... power calculation for ball mills ... Chat Now Bond Mill Power Equation - Protable Plant bond mill index tables. bond mill power equation for sale,prices. throughput, ... bond work index calculation ...

Power consumption and semi-product quality do not change, but the capacity of the roller press increases by at least 10 per cent. To meet the requirements set by the ball mill capacity, the dynamic separator rotor speed of the roller press increases by 2-5 per cent.

High pressure roller press can be introduced as a pre-grinding step for the ball mill, in order to decrease specific power consumption in finish grinding and/or to increase the output of finish mill. Grinding capacity of finish mill increases by about 30%. Up to capacity increases are reported in India with the use of this approach.

• Vertical roller mill (VRM) • Ring roller mill or Horo mill Even though there are various types of systems available for cement grinding, ball mills are predominantly used machines for cement grinding in large number of cement plants. In this paper authors are covering the process diagnostic study of Ball mill for cement grinding. 2.

Finish Grinding | Industrial Efficiency Technology & Measures. Power consumption of this system is reported to be 4~6 kWh/t lower than that of combined grinding system with roller press and ball mill, and 10~15 kWh/t lower than that of ball mill system.

For upgrade projects, using an HRP together with a ball mill significantly reduces overall specific power consumption and increases the system production. In ball mills, less power is required to produce finished cement from HRP pressed material than from unpressed material. TRIBOMAX® the strongest and most durable roller wear surface available.