WhatsApp)

WhatsApp) WhatsApp)

WhatsApp)

Êvertical Êoverhead Êfixed Ê ... §192.225 Welding procedures Welding Performed by Qualified Welder Welding Procedures Qualified Using API 1104 Section 5 or ... welding surfaces must be clean and free of any material that may be detrimental to the weld, and Must be aligned to provide the most

Description: BY series Light Positioner is mainly used for welding of annular weld. The main function of the machine is to tilt, turn the workpiece, so that the weld in the horizontal, ship-shape, suc...

Vertical Roller Mill Working Principle. Material through the feed tube fell on the center of vertical roller mill grinding plate, centrifugal force generated from the rotation of grinding plate uniformly scatters and flattens the materials outwards the surrounding area of vertical roller mill grinding plate, to forms a certain thick layer of materials bed, the material was crushed by number of ...

The HAEUSLER VRM type machine is a universally useable four roller bedning machine with linear hydraulic roll movement of side and bottom rolls. ... The CRWM welding machine has been manufactured to simplify the following internal and external welding seams on longitudinal welded pipes. ... Pipe Mill RB(E)-Procedure. HAEUSLER pipe mills (LSAW ...

weld is rejectable. Ultrasonic Test Ultrasonic testing (UT) is a nondestructive method of detecting the presence of internal cracks, inclusions, segregations, porosity, lack of fusion, and similar discontinuities in all types of metals. It can be used as the sole type of inspection, or it can be used . Chapter 18 Weld Inspection and Repair,

ble experts having worked on more than 30 different models of vertical roller mills for more than 20 cement and power companies throughout the world. From small VRM (roller: Ø 1.65m and table: Ø 2.75m) to huge ... complete welding procedures can be exchanged and are updated on a regular basis. TeroLink ... Vertical Roller Mill repair Type of ...

Jun 07, 2018· The OK mill has been FL's standard cement vertical roller mill (VRM) since 1993. In 2017, FL also introduced the OK raw mill for raw material grinding, designed with the same proven ...

Vertical alignment shall provide for a flat running surface. Any ... specified in the approved welding procedure specification to ensure full fusion of ... and "free weld" for welds not used to control CWR thermal adjustment. E. Verify that each completed weld has full penetration and complete fusion and is entirely free of cracks or fissures.

Risk Assessment Milling Machine (Horizontal and Vertical) 17 February 2016 3 of 4 Ref; Health & Safety Executive Engineering in Workshops the whole of the foot, should be worn when using any machine. Open toed and light canvas shoes are not acceptable, anyone wearing these not be allowed into the D.C.E.D.

Vertical Mill Drills View All. Great for maintenance shops, small fabrication shops, garage shops, a vertical mill drill can handle lighter prototyping needs. Each of these compact hybrid machines also works as a drill press. Read more about Vertical Mill Drills. Vertical Mill Drills

- A groundbreaking wear solution for vertical mills. This latest innovation from Welding Alloys is a fully repairable welded ceramic composite metal matrix alloy providing an optimised engineered wear protection solution for grinding components, setting new standards in the Cement Industry.

A welding procedure was established with the help of Astralloy Technical Services, . Impact crusher or impact stone crusher you can see here . Blow bar crusher parts as impact crusher parts get quite a few shoppers praise, since our blow bars may be very wearable. . welding .

Jun 25, 2016· Report about the repairation of the Raw mill Slide Ring and shell (Modification) ... 33 of 50 MBCC Project Weld the cracks from inside the mill till thickness 5mm below the nominal thickness Start procedures of welding small crack: 1- Reinforce small crack by bars at the ends of cracks according to the procedures of Lionel (Polysius) 2- Small ...

Safe Operating Procedures ... SOP 20 – Feed Mill / Roller Mill Operation & Servicing DO NOT proceed in this operation unless appropriately instructed in its safe use and operation and permission to operate has been given. ... Do not weld on the plant without taking the following steps: a) .

Baileigh Industrial® Holdings LLC. distributes exclusively manufactured metal and woodworking equipment, trusted by customers ranging from large-scale commercial fabrication shops to passionate hobbyists. For 18 years, we've created machines that increase productivity, day in, day out, delivering repeatable quality results.. At Baileigh (pronounced "Bailey"), we build our cutting-edge ...

Welding Techniques in Dentistry 417 2.1. Brazing 2.1.1. Definition The brazing process, also called oxygas or welding with direct flame, produces a coalescence of metals by heating the parts to be welded with a flame. The process needs another type of alloy, called a solder alloy, which is used to join two or more metal parts,

With a vast service and product range in the areas of welding, brazing and coating technologies, we have the solutions for all wear and fusion problems. Your business will become STRONGER with Castolin Eutectic.

In 1954 a Jet Pulverizer was developed in which operates like a Vertical Pulverizer only the item is pulverized by the high speed air action. For example, forcing coal against coal. Bowl mill. Similar to the vertical roller mill, it also uses tires to crush coal. There are two types, a deep bowl mill, and a shallow bowl mill. High speed

STANDARD OPERATING PROCEDURE 'S.O.P' ... After stopping the machine, use a brush or rag to remove all excess chips from the mill bed and stock. Use a rag or Kevlar gloves to handle sharp cutting tools. Cutting tools must be securely fastened in the machine spindle with the proper accessory. Never try to tighten cutting bits or tools by hand.

FIELD WELDING PROCEDURES 4th Edition -June 2011 ... Surfaces to be welded and surfaces adjacent to a weld shall also be free from loose or thick scale, slag, rust, moisture, grease, and other foreign material that would prevent proper welding or produce objectionable fumes. Mill scale that can withstand vigorous wire brushing, a thin rust ...

VAUTID ASW hardfacing welding consumables. VAUTID hardfacing welding consumables can be used in a great variety of applications. They offer a solution to different problems protecting high-wear components in plant and machinery. read more

Thermic welding – Wikipedia, the free encyclopedia. ... Titus manganese or hadfield manganese which guarantees ... Welding Procedure – H-Pile; Welding Procedure – ... ferro alloy thermite process manufacturing flow chart. ... Hardfacing a vertical roller mill - YouTube offers a technique to hard face a vertical roller mill giving the ...

Oct 18, 2017· ️First of all, Happy diwali to all my subscribers and viewers as well.️ Hello guys, I welcome you again in this new fresh topic. This topic is regarding the rolling process used for ...

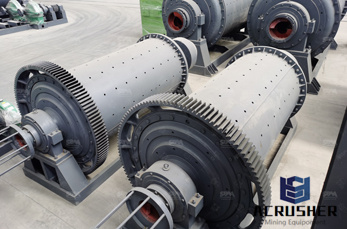

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement. Most cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills.